ENGINEERING

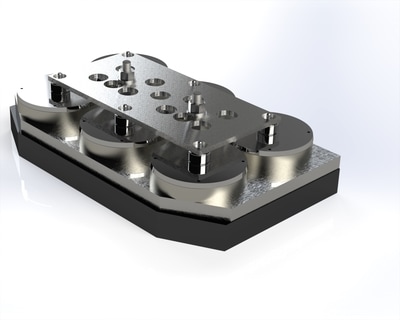

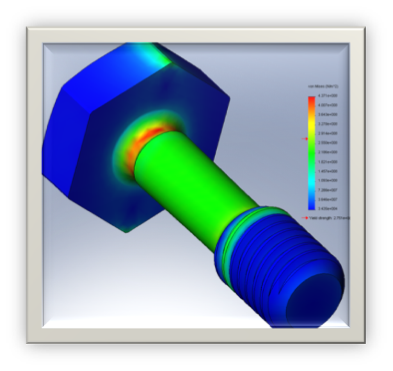

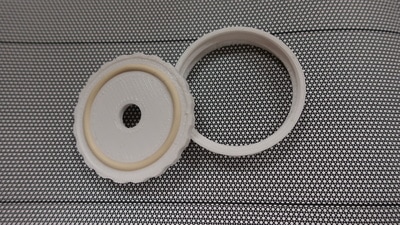

SEM boasts a dedicated internal engineering team that provides invaluable services, enhancing not only the design of our production fixtures but also aiding in reverse engineering efforts. This collaboration allows us to develop improved designs for your components, ensuring we meet and exceed your expectations.

|

|

|

|

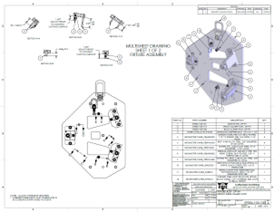

Ideas Into RealityBy utilizing CAD programs like SolidWorks and Autodesk Fusion, we can quickly and accurately generate 3D models and create CNC programs to machine your parts to the accuracy you need.

|

Engineering Services

|

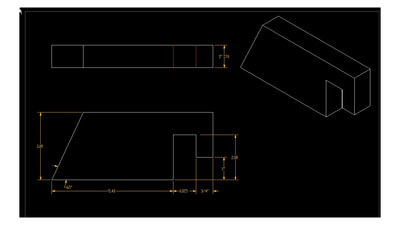

2D Drawings Graphical Representations of data, with all the necessary information to produce your part both now, and whenever you need another. CAD drawings in AutoCad format with your title block.

|

3D Models 3 dimensional representations of your part, that has integrated dimensions, relations, materials, and appearances.

|

EDrawings If you do not have solidworks or other 3D modeling softwares, but still wish to view your model, simply get this model Viewer to fully control your design. Just click here or on the image!

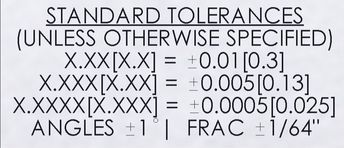

ASME Y14.5 Standards

We at SEM are familiar with both coffee stained hand sketches and thoroughly engineered drawings with tight tolerances, GD&T, and assemblies within assemblies within assemblies. Our current drawings adhere to the latest version of ASME Y14.5 standards of dimensioning and tolerancing

|

Site powered by Weebly. Managed by Bluehost