|

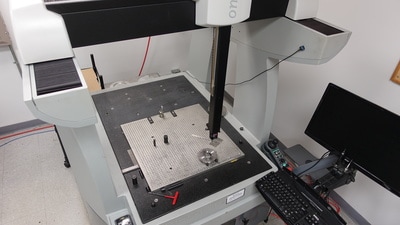

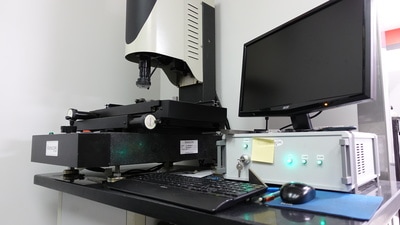

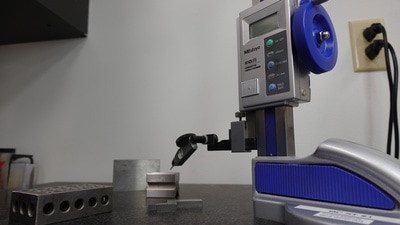

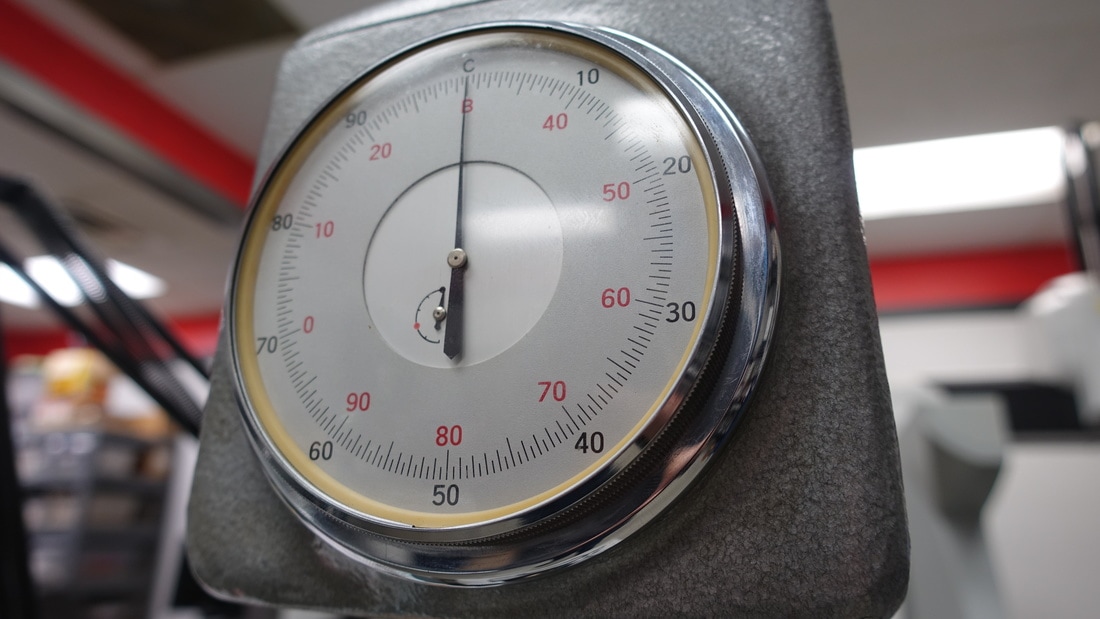

Tight Tolerances?

No Problem. Southeastern Machining offers top notch quality control services as a value added service for our machining and fabrication divisions. All parts are thoroughly inspected after each operation in addition to the final inspection. Upon request custom configured inspection reports can be generated. Our personnel are trained in the latest ASME Y14.5 standards and our equipment software is maintained to the latest version, to ensure our inspections adhere to your drawings standards.

|

|

|

Capabilities:

|

|

Site powered by Weebly. Managed by Bluehost